Tools

Parts

No parts specified.

-

-

For this guide, please refer to the exploded diagram with annoted parts / Bill of Materials.

-

Note: Use the PDF linked diagram above, not the thumbnail provided by Dozuki.

-

-

-

Remove the brim on the smaller end of the arm, and the support material in the two nut traps

-

NOTE: The brim and the support material may have already been removed for you by us, when we packed your kit. but it's best to double-check.

-

-

-

Place flat washer on M3-50mm screw

-

Place screw through 3d printed nut

-

-

-

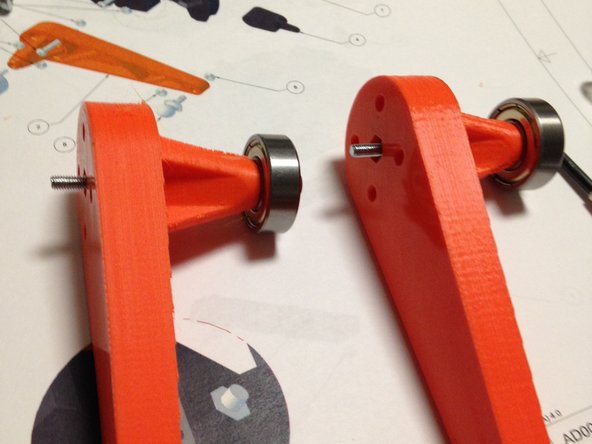

Insert screw into arm

-

Attach M3 nut to back side and tighten until secure and snug, but not so much that the plastic deforms.

-

-

-

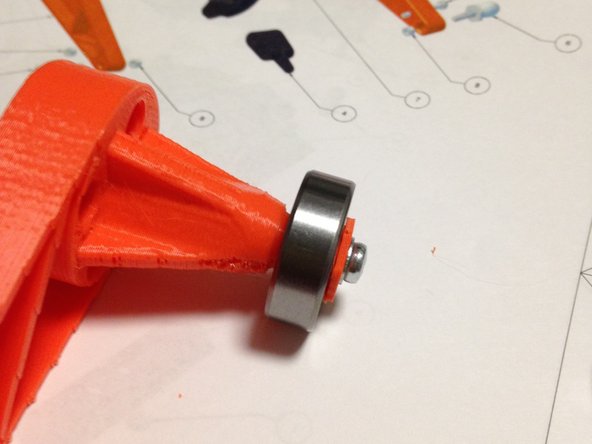

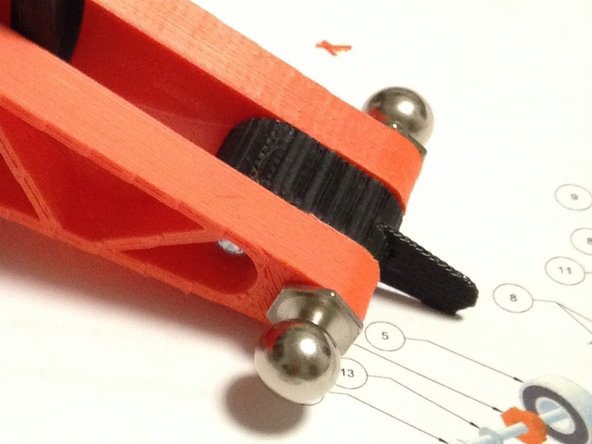

Attach ball-stud to arm

-

Secure with M3 nut. Again, tighten until secure and snug, but not so much that the plastic deforms.

-

-

-

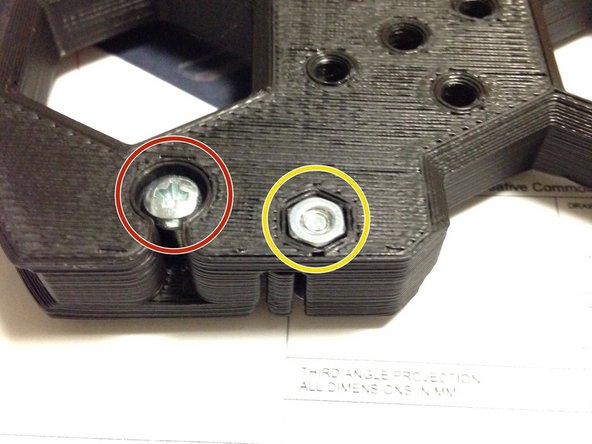

Insert M3 x 12mm L pan-head screw into pulley

-

Secure screw with M3 nut

-

Insert M3 12L flat head screw into opposite side of pulley

-

Secure flathead screw with M3 nut

-

-

-

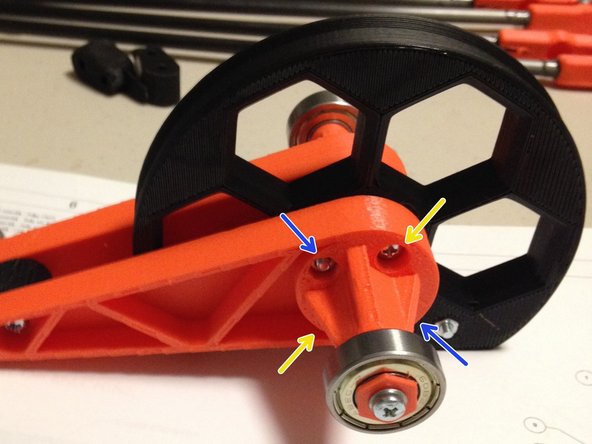

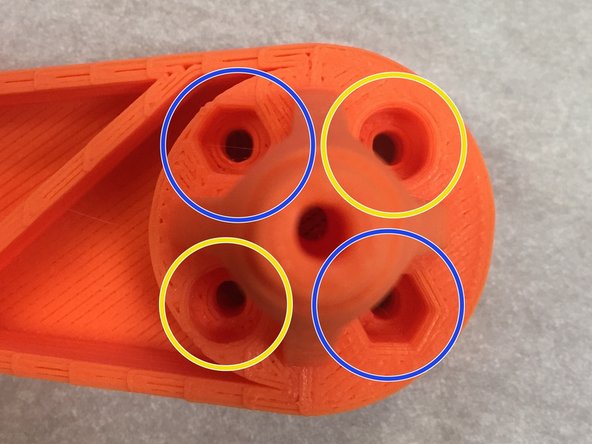

Insert two M3 nuts into each orange arm, as shown in the second picture. NOTE: Only two of the holes will accept nut traps.

-

Insert two M3 x 30mm? pan-head machine screws into each orange arm. NOTE: Only insert the screws into the ROUND counter-bored holes.

-

Carefully assemble both orange arms and the black pulley as shown in the first picture. The nuts and screws are caddy-corner, so when facing each other, everything should line up nicely (nut to screw, etc).

-

NOTE: Do not fully tighten until you complete the next step

-

-

-

Insert 3d printed limit switch interruptor

-

Secure with 20mm M3 screw and nut

-

Tighten all screws

-

-

-

Repeat this guide until you've got three assembled pulleys, as shown.

-

Cancel: I did not complete this guide.

8 other people completed this guide.